Injection Moulding Courses

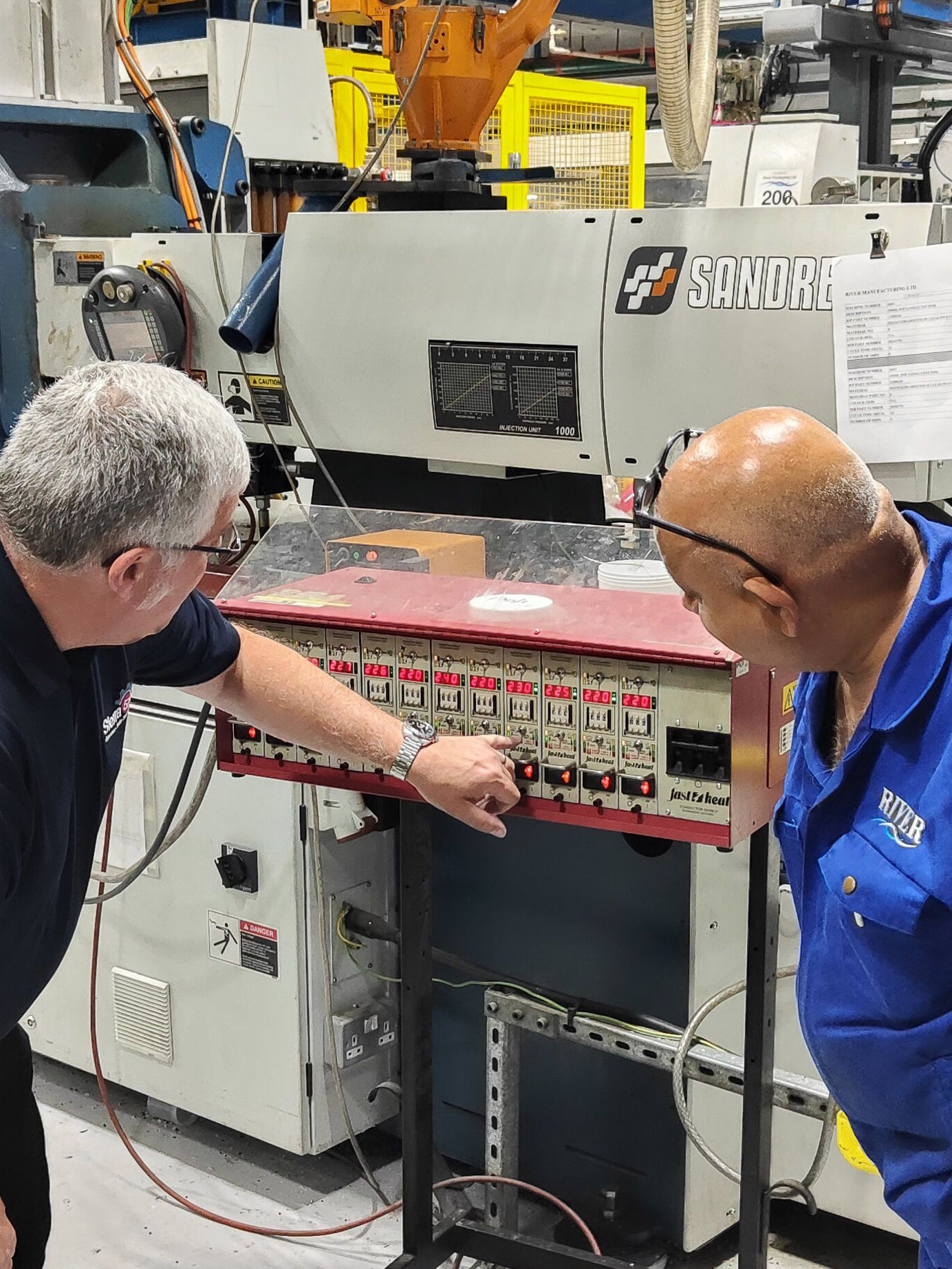

Injection Moulding Courses - The hub and decoupled molding process training, the release also said. An online training solution for part designers, mold designers, and process engineers. Our molders’ series courses feature the latest injection molding technology and research. Some of the topics covered include basic operation of the injection molding machine and secondary equipment, safety on the injection molding production floor and around your molding machines, plus the fast and accurate identification of part defects. The ansi/astm e2659 accredited plastics technology & engineering (pte) certificate program provides a comprehensive education & training solution designed around the primary disciplines of the injection molding industry: This course introduces new hires to the injection molding process. Hoffman, director of the american injection molding institute. Rapid injection molding enables faster prototyping and production, reducing lead times for businesses. Sign up for our interactive injection molding training program today! Plastic materials, mold design & engineering, injection molding, and part design. This course introduces new hires to the injection molding process. Our molders’ series courses feature the latest injection molding technology and research. Our online plastics training programs include comprehensive courses for injection molding, blow molding, extrusion, part design, mold design and moldmaking, blueprint reading and gd&t (geometric dimensioning & tolerancing), and lean manufacturing & quality assurance. Hoffman, director of the american injection molding institute. Learn how simulation can help build proficient injection molders cost effectively. Opportunity for a rate increase after you are proficient in certain skills and have fulfilled training. The course begins with a discussion of the various types of molding machines and considerations when utilizing each type of machine. Rapid injection molding enables faster prototyping and production, reducing lead times for businesses. Injection molding training classes & seminars: Sign up for our interactive injection molding training program today! The hub and decoupled molding process training, the release also said. Our online plastics training programs include comprehensive courses for injection molding, blow molding, extrusion, part design, mold design and moldmaking, blueprint reading and gd&t (geometric dimensioning & tolerancing), and lean manufacturing & quality assurance. Rapid injection molding enables faster prototyping and production, reducing lead times for businesses. Offering a. Our fundamental injection molding courses introduce participants to the machine, material, process, and mold — while covering important safety precautions. Injection molding training classes & seminars: Some of the topics covered include basic operation of the injection molding machine and secondary equipment, safety on the injection molding production floor and around your molding machines, plus the fast and accurate identification. For individuals and small companies, our online training courses and packages can help you develop advanced processing skills — allowing you to optimize any injection molding process. Our molders’ series courses feature the latest injection molding technology and research. The hub and decoupled molding process training, the release also said. The mould is the heart of the injection moulding process.. Our online plastics training programs include comprehensive courses for injection molding, blow molding, extrusion, part design, mold design and moldmaking, blueprint reading and gd&t (geometric dimensioning & tolerancing), and lean manufacturing & quality assurance. High school diploma or equivalent, with additional technical training in plastic processing or injection molding technology preferred. Opportunity for a rate increase after you are proficient. An online training solution for part designers, mold designers, and process engineers. Plastic materials, mold design & engineering, injection molding, and part design. Proficiency in operating injection molding machines, mold setup, troubleshooting machine faults, understanding injection parameters, and performing quality checks. Key considerations include material selection , thermal characteristics , and ease of maintenance. Our injection molding training is built. Offering a wide range of injection molding training options for a large range of personnel. The hub and decoupled molding process training, the release also said. Injection molding training classes & seminars: Injection molded parts serve critical roles in various applications. For individuals and small companies, our online training courses and packages can help you develop advanced processing skills —. Offering a wide range of injection molding training options for a large range of personnel. Uses of simulation in process development. For individuals and small companies, our online training courses and packages can help you develop advanced processing skills — allowing you to optimize any injection molding process. Rapid injection molding enables faster prototyping and production, reducing lead times for. Gain a deeper understanding of what your processes are telling you in order to make improvements and efficiently troubleshoot when problems arise. The process allows for mass production with precision and efficiency. Students can earn an ansi/astm e2659. The ansi/astm e2659 accredited plastics technology & engineering (pte) certificate program provides a comprehensive education & training solution designed around the primary. Gain a deeper understanding of what your processes are telling you in order to make improvements and efficiently troubleshoot when problems arise. The mould is the heart of the injection moulding process. Sign up for our interactive injection molding training program today! Plastic materials, mold design & engineering, injection molding, and part design. Offering a wide range of injection molding. Rapid injection molding enables faster prototyping and production, reducing lead times for businesses. The design of the mould needs to accommodate the desired shape and features of the part while also allowing for efficient production cycles. High school diploma or equivalent, with additional technical training in plastic processing or injection molding technology preferred. Injection molding training classes & seminars: For. The mould is the heart of the injection moulding process. Sign up for our interactive injection molding training program today! Our fundamental injection molding courses introduce participants to the machine, material, process, and mold — while covering important safety precautions. Our online plastics training programs include comprehensive courses for injection molding, blow molding, extrusion, part design, mold design and moldmaking, blueprint reading and gd&t (geometric dimensioning & tolerancing), and lean manufacturing & quality assurance. Students can earn an ansi/astm e2659. Some of the topics covered include basic operation of the injection molding machine and secondary equipment, safety on the injection molding production floor and around your molding machines, plus the fast and accurate identification of part defects. Participants will learn the fundamentals of injection molding processing and strategies for process development, documentation, and troubleshooting; Injection molding training classes & seminars: Our molders’ series courses feature the latest injection molding technology and research. An online training solution for part designers, mold designers, and process engineers. Uses of simulation in process development. Learn how simulation can help build proficient injection molders cost effectively. Rapid injection molding enables faster prototyping and production, reducing lead times for businesses. An overview of various methods for identifying ideal fill times; Gain a deeper understanding of what your processes are telling you in order to make improvements and efficiently troubleshoot when problems arise. Learn how to properly create and maintain a process on an injection molding machine to ensure consistent part quality.Intermediate Injection Moulding Training

Injection Moulding Beginners Training

Injection Moulding Courses Brochure PDF

Home Sierra 57 Plastic Injection Moulding Training Courses

Injection Moulding Beginners Training

Injection Moulding Training Sierra 57 Plastic Injection Moulding

Injection Moulding Setters Training

Advanced Injection Moulding Training Course

Home Sierra 57 Plastic Injection Moulding Training Courses

Injection Moulding Setters Training

The Process Allows For Mass Production With Precision And Efficiency.

Hoffman, Director Of The American Injection Molding Institute.

Offering A Wide Range Of Injection Molding Training Options For A Large Range Of Personnel.

Our Injection Molding Training Is Built On Decades Of Research And Proven Methods.

Related Post: